Not just a "board swap"

Not Just a PCB Board Swap

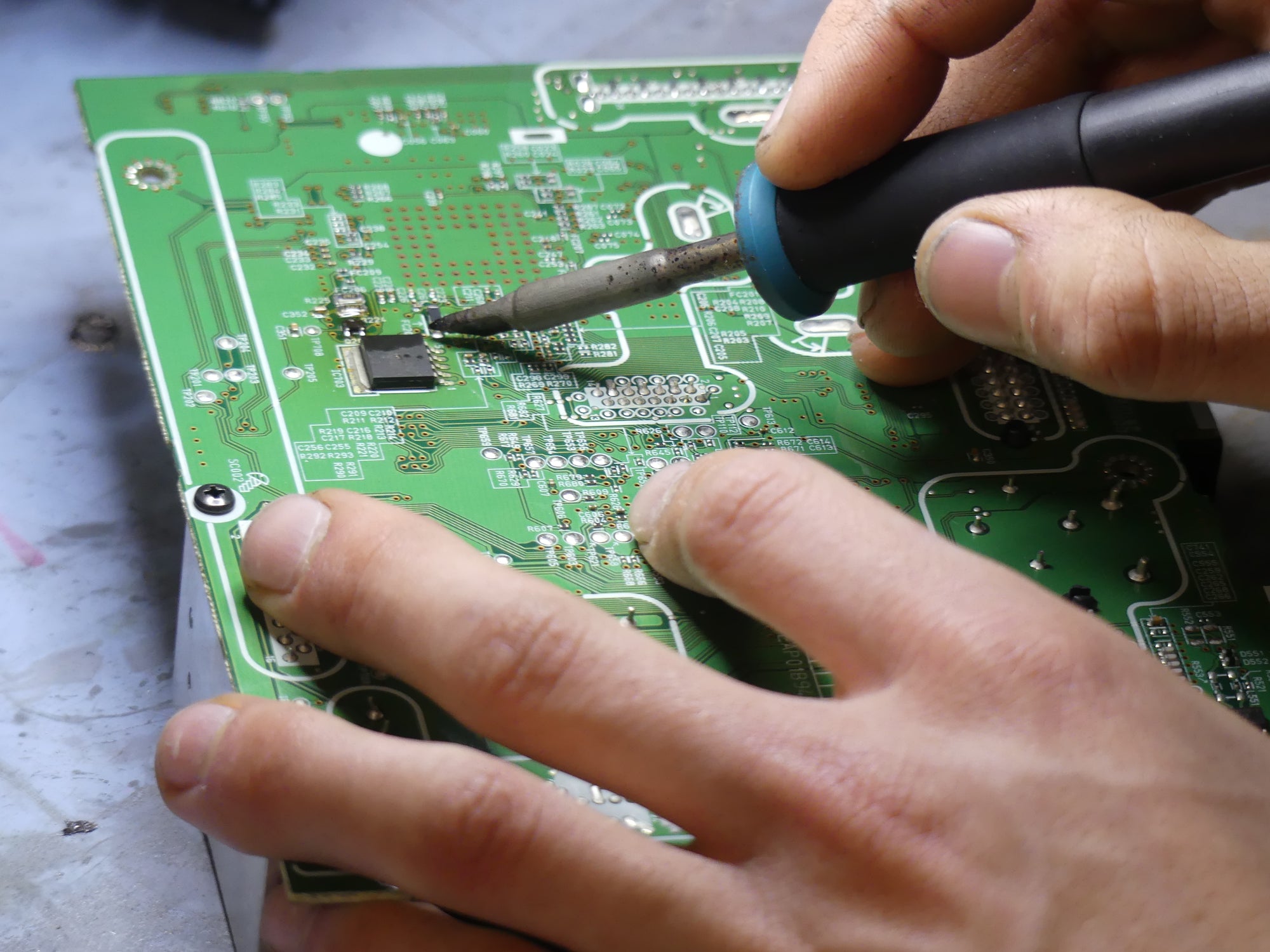

In an age where replacing entire circuit boards has become the norm, true electronic repair has become a rare craft. At our workshop, we don’t just swap out PCBs we go deeper, right down to the individual components that make your equipment function.

Many systems now reaching our benches are over 20 years old. Replacement boards simply don’t exist anymore, and in some cases, the original manufacturers are long gone. This is where real electronics expertise matters.

Our technicians diagnose faults to the component level, tracing failures through layers of circuitry, replacing obsolete semiconductors, rebuilding damaged tracks, and sourcing or even fabricating parts that can no longer be purchased. Each repair is done with care, precision, and an understanding of how the entire system interacts not just the one faulty chip.

This is true repair keeping legacy equipment alive, maintaining valuable assets, and reducing unnecessary waste.

Anyone can replace a board, it takes real skill to bring one back to life.

Some Complex repairs we want to showcase

Here are just a few examples of the many complex repairs we’ve completed demonstrating our expertise, precision, and dedication to keeping your machinery in motion.

Burned Holder No parts Available

We Made this repair happen by cleaning and cutting away the damaged parts then using a couple of connector slugs and used epoxy to make the repair last just as if we brought the correct connector however the customer needed this repair done TODAY, so we Delivered

DC motor Rebuilding

From reshaping carbon brushes to the correct size for proper seating (often completed the same day) to re-dressing commutators on the lathe for smooth electrical contact, our team ensures every motor runs like new.

Trace that Pin

Tracing an electrical pin from the main connector is no easy task. Sometimes that signal disappears deep into the circuit —but that’s what we do best getting to the root of the problem and bringing control systems back to life.

Thermal Imaging

Just like our electrician customers who use thermal cameras to find hot spots in electrical cabinets, we do the same but on a much smaller scale.

By scanning control boards and circuitry, we can pinpoint overheating components, shorted tracks, or failing parts

Common Repairs in our facility

HMI Factory Displays

AB VFDs

Motor Testing

Excavator Screens

Panasonic Drives

Welder Repairs

Fanuc